Liquid Filled Pressure Gauge – The Multipurpose Device to Ponder Upon

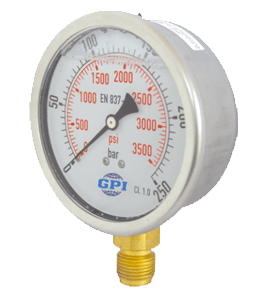

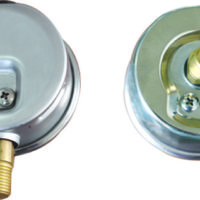

GPI’s liquid filled pressure gauges are perfectly manufactured to function in different adverse conditions. They are either filled with glycerine or silicone oil and are engineered to perform better than the traditional dry gauges. The magnificent performance and the improved ROI allow the potential buyers to rely on GPI’s precision instrument more.

But Why GPI’s liquid filled pressure gauge?

Because we offer you the most premium quality liquid filled pressure gauge at a reasonable rate. These include:

High Durability:

Unlike the dry traditional gauges, these liquid-filled gauges possess high longevity due to the presence of viscous fluid. Since this lowers the risk of unscheduled downtime, the device does not involve high instrumentation or maintenance costs.

Greater Accuracy:

Due to the presence of the viscous fluid the fluctuations of the temperature is controlled to a great extent. With GPI’s liquid filled pressure gauge you can witness greater accuracy and high process control, allowing the users to continue their work seamlessly.

Moisture Resistant:

Our high-quality pressure gauges are designed in such a manner that they can prevent moisture from entering the tool. Such an engineering tool, therefore, works in a flawless manner in high-humidity environments.

Corrosion Resistant:

Our liquid-filled gauges are constructed in such a way that they can be used in highly corrosive environments. They are designed to serve every rugged specification. Be it any highly-corrosive chemical processes, refining processes, or any other temperature condition, GPI’s liquid-filled gauge is ready to meet the situation.

Looking for such effective liquid filled pressure gauge? Get in touch with us. Our quality products and the price rate will never depress you.